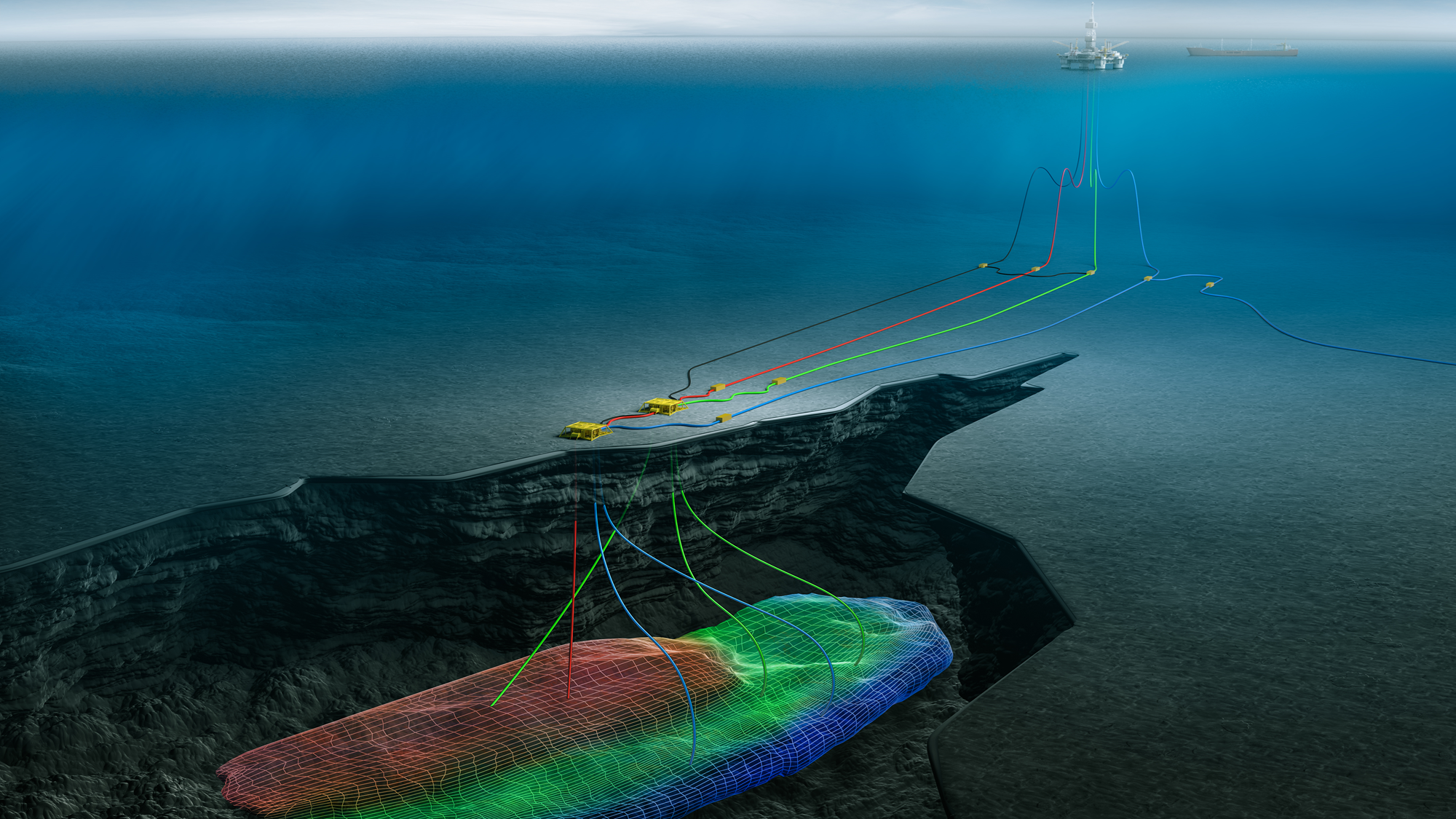

Subsea Systems, Pipelines and Risers

Reinertsen New Energy has more than 40 years of experience from engineering of subsea infrastructure.

Reinertsen New Energy provides engineering services including well systems, subsea production facilities, subsea infrastructure and transport to the receiving facilities offshore or onshore.

Reinertsen New Energy is an independent supplier of services to the oil and gas companies in the following areas:

Systems engineering: Subsea Umbilicals, Risers and Flowlines (SURF) and Subsea Production Systems (SPS).

Field architecture and routing of subsea lines.

Flow assurance.

Engineering and design of subsea systems, pipelines and risers.

Materials selection, corrosion and cathodic protection.

Seabed intervention and pipeline protection.

Installation and Tie-ins.

Landfall design.

The role as “Owner’s Engineer", performing project support, independent engineering studies and verification work.

ConocoPhillips 2024 – 2025

Power from Southern North Sea 2 (Sørlige Nordsjø 2)

The SURF Design FEL-2 study investigated possible solutions for routing, installation and tie-in of subsea power cables connecting Ekofisk and Eldfisk Complexes to the SNII Wind Farm.

The work included:

Input to Design Basis and Functional Spec for subsea cables

Layout and route design including platform approach

Identify and describe all crossings and crossing design

Trenching and rock installation solution for selected route

Subsea cable stability and in-place design

Evaluation of interaction and interference with live assets

Evaluation of installation and tie-in methods

Cable pull-in design / suitability of nominated J-tubes.

Dropped object assessment and protection design

Input to Material Take Off

Input for crossing agreements.

Input for environmental impact assessment

ConocoPhillips 2023 – 2025

Previously Produced Fields (PPF)

Concept development and Pre-FEED of the subsea tie-back of West Ekofisk, Albuskjell and Tommeliten Gamma to Ekofisk Z.

The work included:

Systematic evaluation of potential development concepts

Perform sufficient engineering to recommend SPS concepts

SURF engineering

Flow Assurance

Materials engineering and CP-design

Cost and schedule estimates

System design responsible

Follow-up of EPCI contractors

Design verification

Vår Energi 2023 – 2025

Beta & Dugong

We provide owner’s engineering services in early project phases for the subsea tie-back of the Beta & Dugong fields to the Snorre field.

Reinertsen New Energy is integrated in company’s project team to cover technical advisory services within Subsea Umbilicals, Risers and Flowlines (SURF), and within Subsea Production Systems (SPS)

ConocoPhillips 2019 – 2025

Tommeliten Alfa

Pre-FEED, FEED and detail engineering & follow-up of the Tommeliten Alfa subsea tie-back project:

System design responsible

SPS design (Template, Xmas tree system, Control system, manifold system, Subsea HIPPS, Tooling)

SPU system (Separation technology, Flow measurement, Pump design)

SURF design (Field layout, Flowline design, Umbilical design)

Flow Assurance design

Evaluation of available J-tube solutions

Cost and Schedule estimates

Follow-up of EPCI suppliers

Vår Energi 2019 – 2025

Gjøa Subsea Projects

Reinertsen New Energy is providing the necessary technical expertise and resources required to secure handling of Vår Energi’s technical responsibilities as operator for the Gjøa Subsea Projects, i.e. P1&Duva, Gjøa Nord, Ofelia and Cerisa.

SPS advisor in the project team

SURF advisor in the project team

Material advisor in the project team

System engineering

Review, verifications and follow-up of study contractor’s work (SURF & SPS)

Pipeline corrosion evaluations

Shell (Norway) 2017 – 2025

Ormen Lange Phase 3 – FEED, Post-FEED and Detail Design

Landfall design (Landfall trench, Umbilical pull-tubes w/bellmouth and endcaps)

Field layout design

Pipeline routing and design, expansion and VIV analyses, and input to ECA

Umbilicals routing from Nyhamna to the field, 2x120 km

Umbilicals bottom roughness and free span analyses

Protection and Seabed intervention design; Pre-lay and Post-lay Rock installation vs. Trenching

Geotechnical engineering of all Seabed intervention work

Follow-up of subsea rock installation work

Follow-up of trenching operations

Assurance support; review of manufacturing documents and procedures, follow-up of procurement, qualifications and fabrication activities

Interface management

Chevron/Vipo 2022 – 2024

Janz-Io Compression / Retrofit insulation

The Jansz-Io Compression retrofit insulation scope involved retro fitting of thermal insulation to the existing and operating 30” export spool between the Jansz MPTS and the Jansz PLET at a water depth of ca. 1350 m.

The overall work scope included the engineering and qualification of a suitable ROV installable, and recoverable retrofit insulation system, which enables management of localized internal condensation with risk of localized corrosion through the provision of thermal insulation.

Suitable thermal insulation covers designed for the different spool sections. The scope covered the qualification of a suitable retrofit thermal insulation subsea system, as well as securing that the CP system will be functional during the remaining lifetime of the spool after retrofit insulation.

Reinertsen New Energy was responsible for the engineering design including Thermal Analysis, CP Analysis, Structural Analysis, Installation Analysis, and the Monitoring requirement study.

Neptune Energy 2017 – 2022

Fenja project

Reinertsen New Energy provided the necessary technical expertise and resources required to secure handling of Neptune Energy's technical responsibilities as development operator from the Front End Engineering Design (FEED) phase throughout the Fenja project execution phase (EPCI).

The work included:

System engineering

Lead SURF engineer

Lead Pipelines engineer

Lead Material engineer

Technical safety

Risk Based Inspection Program

Technical support and verification activities

Follow-up of EPCI-contractor (SURF & SPS)

Offshore surveillance

Quality & Audit support

Seabed Separation AS 2018

Dual pipe separator

Development of an installable concept for a subsea dual pipe separator.

The work has been an early phase assessment of system design, equipment needs and assessments of the extent of marine operations.

The separation system includes the flexibility to contain several equipment packages depending on specific field requirements, both in relation to fluid capacity and the need for water injection and/or multi-phase boosting.

Woodside 2017

Browse Field Development

Concept select phase Browse Field Development:

Our scope of work included:

Confirm technical feasibility of DEH for Calliance/Breaknock and Torosa subsea flowlines

Provide sufficient equipment details, functional descriptions, weights and dimensions.

Establish a Class 1 cost estimate.

Identify any risks or opportunities associated with DEH systems for the Browse facilities.

ConocoPhillips 2017

Ekofisk Water Injection (EKOVC)

Engineering Services related to the EKOVC water injection project including preparation of project design basis and project specifications.

The work also comprised design document review, design verifications and procurement support for CPI deliveries.

TechnipFMC 2017

Luno II Trawl Assessment

Support to TechnipFMC on the FEED for the Luno II – Value Engineering.

Four satellite wells on the Luno II field (2 production and 2 WI) are planned to be tied-back to the Edward Grieg platform (20 km).

Our scope of Work included a Trawl Assessment study evaluating the trawl interference of the Umbilical and Gas lift lines (i.e. impact, pullover, hooking) and the protection requirements.

Statoil 2011 – 2015

Åsgard Subsea Compression

Detail design of the subsea pipeline system. The work started with a refinement and update of the FEED results from 2010.

The scope comprised overall layout, routing and design of flowlines, MEG lines, power cables, umbilicals and fiber optical cable (FOC) to/from the compressor station, existing templates/PLEM’s, hot-taps on the Midgard loop and Åsgard A and B, including all associated seabed intervention work.

Further design of all tie-ins and expansion spools (21 off), PLEM/PLET/Riser Base structures (19 off) and verification of the compressor manifold station (SCMS).

A new spool design guideline to be developed as part of the project in cooperation with DNV.

Development of MTO’s, input to ITT’s and assistance to Company with contracts for prefabrication of structures and installation of lines and structures, and follow-on engineering services during the fabrication and installation phases.

ConocoPhillips 1995 – 2015

Ekofisk Area Frame Agreement

Frame agreement covering all phases of SURF projects in the Ekofisk Area:

1995 – 1997 Ekofisk II verification

1997 Eldfisk Water Injection Detail Engineering

1997 Ekofisk II Fuel gas line – Detail Engineering

1997 – 1999 Ekofisk II/Eldfisk – Basic Engineering

1999 – 2000 H7 Subsea Bypass – Concept & Basic Eng

2003 – 2005 FTP Bypass – Detail Engineering

2006 Eldfisk Upgrade – Detail Engineering

2006 Eldfisk 2 – Conceptual Study

2009 – 2009 Norpipe B11 Bypass – Detail Engineering

2009 Norpipe Looping – Conceptual Study

2012 – 2013 Tor II – FEED Study

2013 – 2014 Tommeliten Alfa – Conceptual Study

2013 Norpipe / Teeside – Conceptual Study

2015 Tommeliten Alfa – FEED Study

Wintershall 2013 – 2014

Maria Subsea FEED

The Maria subsea facility is tied via rigid flowlines and flexible risers to Kristin with gas lift being supplied from Åsgard B via Tyrihans and Sulphate reduced sea water supplied with injection pressure from Heidrun.

The Maria Subsea FEED project covered the following engineering activities included:

System Engineering

Flow Assurance

SPS System; X-mas trees, manifold, workover

Control System

Pipeline System

Pipeline components (SSIV, PLEMs and PLETs)

Riser System

Umbilical System

Cost & Schedule

BP Norge 2005 – 2014

Skarv Field Development

Evaluation for location of FPSO

Number of and size of flowlines

Flowline and Export pipeline route alternatives

Concept evaluation of expansion control. Perform bottom roughness analyses and fatigue assessment of pipeline free spans. Evaluate requirements and methods for mitigation of free spans. On-bottom stability analyses

Corrosion allowance evaluation. Material Evaluation. Initiate comprehensive test program (Sintef/Bodycote) to support Flowline material selection

Wall thickness and stability calculations of all piping

Bundle vs. Single line evaluation (price estimates, risk and interv. design)

Complete schedule / Budget for fabrication and installation

ITT technical input (e.g. piping; material, fabrication and installation)

Assisted in material purchase in Germany and Japan

DEH at Sintef; dimensioning of cable

Seabed intervention and estimation of rockdump infill volumes

Statoil 2007 – 2010

Ormen Lange Southern Field Development

Tie-back of Template D to the Phase I gas transportation pipelines going to the Nyhamna onshore process facilities.

The flowline system includes 2 x 16” production lines, a 6 5/8” MEG line and a control umbilical. Each line is 13 km long.

The development area is in 850 m water depth and the seabed is very irregular with very soft clay and stiff clay features.

Detail and follow-on engineering design for flowlines, umbilicals and protection structures.

Main topics included:

Field lay-out architecture and flowline routing

Flowline and coating design

Pipe–soil interaction definition

Free span, fatigue and expansion design

Tie-in spool design

Seabed intervention design (excavation, rock dumping, jetting)

CP design

HSE engineering including dropped object analyses

Lead interface

Offshore supervision and onshore duty service